Pacamor Kubar Bearings(PKB) Awarded Contract to Support Mars 2020 Mission

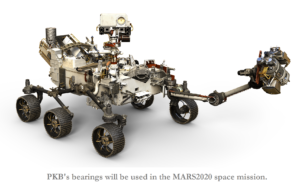

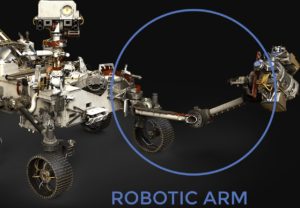

Pacamor Kubar Bearings (PKB), a Troy, NY manufacturer of ball bearings for aerospace and defense systems, was recently awarded a contract by Sierra Nevada Corporation (SNC) to supply critical hardware for the Mars 2020 mission. Scheduled to launch in 2020, the robotic science rover will investigate key questions about the habitability of Mars and assess natural resources and hazards in preparation for future human expeditions to the red planet. Under the new contract, PKB will manufacture ball bearings for several motors in the robotic arm actuator and sample caching system. The instruments will enable scientists to identify and select a collection of rock and soil samples that will be analyzed and stored for potential return to Earth.

Pacamor Kubar Bearings (PKB), a Troy, NY manufacturer of ball bearings for aerospace and defense systems, was recently awarded a contract by Sierra Nevada Corporation (SNC) to supply critical hardware for the Mars 2020 mission. Scheduled to launch in 2020, the robotic science rover will investigate key questions about the habitability of Mars and assess natural resources and hazards in preparation for future human expeditions to the red planet. Under the new contract, PKB will manufacture ball bearings for several motors in the robotic arm actuator and sample caching system. The instruments will enable scientists to identify and select a collection of rock and soil samples that will be analyzed and stored for potential return to Earth.

“PKB has been supporting NASA’s Jet Propulsion Laboratory (JPL) programs and missions for over 10 years,” said Ed Osta, president of Pacamor Kubar Bearings. “We are grateful for NASA and SNC’s continued confidence in our ability to produce reliable aerospace bearings for these vital missions. PKB is committed to the success of this mission and proud to partake in this project. We look forward to continuing our longstanding relationships with JPL and SNC.”

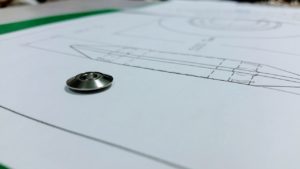

PKB understands the unique challenges presented by aerospace and guidance applications. Temperature extremes and the vacuum of space create demanding requirements for the lubricant type and its ability to withstand the environment. To meet this demand, PKB is providing precise and reliable products in support of successful missions.

“SNC appreciates the PKB’s commitment to deliver the promised product within the assured timeline,” said Jason Priebe, vice president of productions/operations for SNC’s Space Systems business area. “Reliable suppliers are crucial to developing a final product that you’re proud to stand behind.”

ABOUT PACAMOR KUBAR BEARINGS

PKB is ISO9001:2015 and AS9100D certified, which includes the additional QS requirements specific to the aerospace industry. The company attained certification from the FAA to manufacture bearings per the requirements of TSO-C149, thereby enabling it to provide bearings as replacement parts to FAA certified repair stations. PKB is JCP-Certified, which is a joint certification program with United States and Canada.

Pacamor Kubar Bearings manufactures high performance DFARS-compliant miniature and instrument ball bearings for the aerospace, defense, medical, industrial and commercial industries. Customers include major aerospace manufacturers and key re-sellers as well as various national laboratories and prestigious government organizations such as NASA. PKB provides these industries with precision ball bearings, including those with unique designs and materials used at sub-cryogenic temperatures.

For more information on PKB, please follow us on our facebook page, and on our instagram feed.

Pacamor Kubar Bearings offers the right bearing at the right price, for all your miniature, precision, and instrument applications.

Getting The Most Out Of High-Speed Bearings

- Made in Troy, NY USA

- AMERICAN owned and operated Small Business

- VETERAN owned and operated

- DFARS-compliant

- ISO 9001:2015 certified

- AS9100D certified factory

- FAA TSO-C149 Aircraft Bearings

- ISO 14644-1 Class 6 Clean Room

- ISO 14644-1 Class 5 Clean Benches

- U.S. / Canada JCP Certified

- In-house DMIR for expedited aerospace projects

- Lowest prices of ANY domestic ball bearing manufacturer. Let us show you!

Speed is affected by many factors, including bearing geometry. Bearing rings must be ground to tight tolerances and polished to a smooth and shiny finish. Bearing steel must be of high quality with small, evenly spaced carbides. Large carbides and inclusions reduce the quality of the steel and create “tear outs” and “comet tails” in the raceway; this slows the bearing and shortens its operating life. Finally, retainers must be piloted so they do not drag on any of the bearing components. Retainer drag slows the bearing and results in premature assembly failure.

How-To Guide: Estimating Life of Miniature Ball Bearings

“Life” is the number of hours that a percentage of similar bearings have survived under an essentially identical set of operating conditions and loads. Life can be affected by a number of factors including loads, speed, lubrication, fit, maintenance, temperature, contamination, and others.

Bearing life is defined as the length of time (number of revolutions) until a specific failure occurs. Predicting the life of a ball bearing is a statistical calculation of the fatigue properties of the various bearing components. Fatigue Life (L10 or Rating Life) of bearings is the number of hours or revolutions reached by 90% of a group of bearings subjected to the same loads before the onset of fatigue. Conversely, 10% of the same group of bearings can be expected to show evidence of fatigue before the L10 Life is reached.

Many variables can impact bearing life. Various factors such as handling and contamination damage can dramatically reduce bearing life. Bearings should be properly stored, mounted, dismounted, and inspected. Optimized performance and life is also contingent on appropriate lubrication and sufficient protection from foreign matter. Bearings should be stored in a cool, clean, low humidity environment free of dust, shocks and vibrations. Proper fitting, using specialized tools and techniques, will also help maximize bearing life.

For further assistance with bearing selection and design, please feel free to contact our engineering team. Catalog bearings, of all sizes produced by PKB, can be configured as Angular Contact, Radial, or Full-Complement types. PKB also manufactures a wide range of Thin-Section and Metric bearings.

For further assistance with bearing selection and design, please feel free to contact our engineering team. Catalog bearings, of all sizes produced by PKB, can be configured as Angular Contact, Radial, or Full-Complement types. PKB also manufactures a wide range of Thin-Section and Metric bearings.

See our Bearing Installation Guide & Bearing Handling Practices pages for more information about proper installation of a PKB bearing into your device. Be sure to visit our Shaft and Housing Fits page for a detailed chart and more information about this topic.

For further assistance with bearing selection and design, please e-mail sales@pacamor.com

PKB Is U.S. / Canada Joint Certification Program (JCP) Certified

Pacamor Kubar Bearings (PKB) is JCP Certified. A Joint Certification Program is required by U.S. or Canadian Government Contractors wanting to obtain access to unclassified technical data drawings disclosing military critical technology with military or space application that is under control of, or in the possession of, the U.S. Department of Defense (DOD) or the Canadian Department of Defense.

Some historical JCP background

The United States (U.S.) and Canada:

- Share a unique, long-standing military and economic relationship.

- Are partners in the joint defense of North America and have established a bilateral common structure (NORAD) for mutual defense

- Consult and cooperate on the development of common industrial security procedures and technology controls

- Have entered into numerous bilateral agreements that codify and support this relationship

- In 1985, signed a Memorandum of Understanding (MOU) that established the U.S.-Canada Joint Certification Program (JCP)

The JCP:

- Was established to certify contractors of each country for access, on an equally favorable basis, to unclassified technical data disclosing critical technology controlled in the U.S. by Department of Defense (DOD) Directive 5230.25 and, in Canada, by the Technical Data Control Regulations

- Is managed by the U.S./Canada Joint Certification Office (JCO)

The JCO:

- Is a common, jointly staffed office

- Receives and processes the DD Form 2345

Custom Bearings For Cold Applications

Angular Contact bearings are available with relieved inner or relieved outer ring configurations and are built as either separable or non-separable assemblies. Many retainer material options are readily available for all designs. Contact us to discuss our wide range of popular and hard-to-find materials. All bearing sizes are FAA TSO-C149 Aircraft Bearings and any of them can be heat treat stabilized for Cryogenic Applications

Cryogenic Stabilization

We’re pleased and honored to share a very nice testimonial, from the CEO of Hoffer Flow Controls, about the superior performance of PKB Cryogenic Bearings in their Flow Control Units.

Speaking of cold. There are no snow days for us. We’re here for you, even in extreme weather conditions.

Quality Certified Domestically Produced

The entire Pacamor Kubar Bearings(PKB) Domestically Manufactured Ball Bearings Catalog is FAA certified for use as FAA TSO-C149 Aircraft Bearings, and are appropriately DFARS approved and Domestically Manufactured at our ISO9001:2015 & AS9100D Quality Certified Factory in Troy, NY.

Pacamor Kubar Bearings(PKB)

145 Jordan Road, Troy, New York 12180

How-To Guide: Proper Lubrication Of Miniature & Instrument Ball Bearings

How-To Guide: Proper Lubrication of Miniature & Instrument Ball Bearings

Bearing lubrication is an essential element of bearing selection. Proper lubricant can reduce friction, prevent bearing wear, protect bearing surfaces from corrosion, and carry away excess heat from bearing operation. Pacamor Kubar Bearings(PKB), selects only bearing approved and tested oils and greases for our wide variety of lubricant options. Bearings operate on a very thin film of lubricant which must be maintained, or replaced, to ensure that maximum bearing life is achieved.

Bearing lubrication is an essential element of bearing selection. Proper lubricant can reduce friction, prevent bearing wear, protect bearing surfaces from corrosion, and carry away excess heat from bearing operation. Pacamor Kubar Bearings(PKB), selects only bearing approved and tested oils and greases for our wide variety of lubricant options. Bearings operate on a very thin film of lubricant which must be maintained, or replaced, to ensure that maximum bearing life is achieved.

Proper selection, application, and maintenance are vital in maximizing bearing life. Using the proper lubrication in the bearing will reduce friction and wear. This is achieved by creating a hydrodynamic film of appropriate thickness and strength to support the load while separating the balls from the raceway.

How Does Lubrication Impact Bearing Life?

Bearing lubrication prevents against metal to metal contact. It also minimizes retainer wear by reducing friction. Proper lubricant will conduct heat away from the bearing. Operational conditions such as temperature, loads, speed, torque, and environment determine the lube appropriate for the application.

Should I choose Oil, Grease, or Dry-Film Lubricant for My Application?

Dicronite-coated bearings*

Oils are used where low bearing friction torque is a primary concern. Grease may provide longer operating life and resist lubricant loss due to centrifugal forces at higher speeds. Dry-film lubricant, such as Dicronite, is often appropriate for vacuum environments or other conditions where wet lube is not an option. Pacamor Kubar Bearings(PKB) offers bearing lubrication in grease form, oil lubricants, and solid dry film lubricants.

*You can find more info. on Dicronite, here.

What is Wettability and Why is it Important?

Wettability is the ability of a liquid to maintain contact with a solid surface. A bearing that is contaminated with two different surface treatments (intentional or unintentional contamination by other lubricants, soaps, detergents, hand cream, food products, etc), could result in a non-wettable condition on the raceway. In simplest terms, think about driving a car on the highway and the weather turns stormy. Rain pours onto the highway, mixing with the gas, oil, rubber, and other debris that was already coating the road. The road becomes very slippery in some places and not as slippery in others. The automobile’s tires slip and then gain traction and then slip again, on the differently lubricated surfaces of the road.

When Should Bearings be Re-Lubed?

Bearings should be re-lubed at the recommendation of the bearing manufacturer, when the bearings have been subjected to temperature conditions outside of the recommended temperature range, if the bearings have become contaminated, if the original packaging has become damaged, if you’re unsure of the lubricant’s expiration date, if there is any question about the quality, condition, or type of lubricant in the bearings, or if the bearing lubrication appears to have separated, discolored, or otherwise changed appearance.

Can I Wash out the Lubrication and Install New Lube?

Many 440C Stainless Steel Bearings that are used in Aerospace, Medical, and other applications can be cleaned and re-lubricated, in proper clean room conditions and by properly trained personnel. Improper handling can result in cross contamination, problems with wettability on balls & bearing races, or ball & raceway damage, as well as broken, cracked, lost or otherwise unusable retainers, seals, shields, or wires. PKB provides bearing wash and re-lube services, for many aerospace OEM’s and authorized re-sellers, in our factory clean room.

PKB maintains an extensive inventory of popular lubricant options. Dry-film lubricants are also available upon request.

For further assistance with bearing selection and design, please feel free to contact our engineering team.

See our Bearing Installation Guide & Bearing Handling Practices pages for more information about proper handling installation of the PKB bearing into your device. Be sure to visit our Shaft and Housing Fits page for detailed information about this topic.

Other Recent Blog Topics:

- See our Shaft and Housing Fits page for a detailed chart and more information about this topic.

- See our Bearing Handling Practices blog, for more information about proper handling installation of PKB bearing, for improved bearing performance and life.

- See our Bearing Installation Guide page for more information about proper handling installation of PKB bearings into your device.

For further assistance with bearing selection and design, please feel free to contact us at sales@pacamor.com

Pacamor Kubar Bearings manufactures DFARS approved FAA TSO-C149 Aircraft Bearings in our ISO 9001:2015 certified factory in Troy, NY.