How-To Guide: Shaft & Housing Fits

Pacamor Kubar Bearings(PKB) is continuing our HOW-TO GUIDE series with some suggestions for selecting the proper bearing fit on a shaft or in a housing. We hope this will help you to maximize bearing life and performance.

How-To Guide: Choosing the Best Fit between the Bearing & Shaft, or Housing

Planning for proper fit between the ball bearing and the shaft or housing is as important as bearing design and cleanliness. Improper bearing fits or incorrect installation can damage the bearing assembly.

This guide is for establishing shaft and bearing fits for miniature and instrument bearings when the expansion coefficients of the shaft and housing are similar or when the operating temperature differential between them is nominal. In other conditions, modification in fits and internal clearance may be required. See our Bearing Installation Guide & Bearing Handling Practices pages for more information about proper handling installation of the PKB bearing into your device. Be sure to visit our Shaft and Housing page for a detailed chart and more information about this topic.

Some Tips:

- Within the assembled mechanism, the fit of the ball bearing on its mating components is vital to maximizing bearing life.

- If the fit is too loose, the bearings slide around on the shaft, eliminating the advantages gained by selecting a ball bearing in the first place.

- If the fit is too tight, the bearing integrity may be compromised by reduction of radial play in the assembly.

- The perfect fit enables bearings to run at peak performance for maximized end-product life.

- There are three main types of shaft and housing fits.

- A loose fit is when the bore of the inner ring is slightly larger than the outer shaft diameter.

- A line-to-line assembly is when the bore of the inner ring of the bearing and the outer diameter of the shaft are the same.

- With a tight fit, the bore of the inner ring of the bearing is slightly smaller than the outer shaft diameter. Tight fits are also called interference or press fits, because bearings in these assemblies are pressed onto shafts.

- Slightly loose shaft-to-housing fits are suitable for most applications, while line-to-line fits often provide the best performance.

- If bearings are assembled on a shaft that is too large (creating a press fit) the inner ring may stretch slightly. When this occurs, the bearing’s radial play can be diminished or even eliminated altogether.

- See our Shaft and Housing Fits page for a detailed chart and more information about this topic.

- See our Bearing Handling Practices page for more information about proper handling of PKB bearing, for improved bearing performance and life.

- See our Bearing Installation Guide page for more information about proper installation of PKB bearings into your device.

For further assistance with bearing selection and design, please feel free to contact sales@pacamor.com

Pacamor Kubar Bearings manufactures DFARS-approved FAA TSO-C149 Aircraft Bearings in our ISO 9001:2015 certified factory in Troy, NY.

Angular Contact (Separable & Non-Separable), Thin-Section, Full-Complement Ball Bearings

Award Winning Defense Supplier

Four NEW Product Lines To more fully support the needs of our country’s defense programs, Pacamor Kubar Bearings (PKB) has expanded its ball bearing factory capabilities with four important new product lines. PKB is now producing Full-Complement Ball Bearings, Thin-Section Ball Bearings, Separable Angular Contact Ball Bearings, and Non-separable Angular Contact Bearings alongside such legacy bearing products as Radial Ball Bearings, Cryogenic Ball Bearings, Metric Ball Bearings, FAA TSO-C149 Aircraft Bearings, and Specialty Ball Bearings.

All of PKB’s ball bearings, including FAA TSO-C149 Aircraft Bearings, are appropriately DFARS-approved and Domestically Manufactured at the ISO9001:2015 & AS9100D Quality Certified Factory in Troy, NY.

Ed Osta, President of Pcamor, stated, “Product quality from PKB is excellent. We’re a very customer focused business. Customers have made it known that these four products are desirable to them. Our customers are our greatest asset, and our existence depends on responding to their ever changing needs. These four new products that we’re introducing today are a direct result of specific customer requests.”

PKB continues to invest in its factory capabilities with the recent addition of a Cincom A32 lathe to its primary turn capabilities. This state of the art lathe expands machine capacity and production efficiencies within the Troy, NY ball bearing factory. The Cincom A32 is reputed to be the world’s fastest Swiss type CNC automatic Lathe.

The new lathe enables PKB to shorten its uniquely compact factory lead time of 8-10 weeks for standard bearings and respond more quickly to new and unique ball bearing requests from the aerospace community.

Enhanced products, as a result of this new lathe, will include shaft and bearing assemblies and expedited responses to time sensitive prototype requests.

Award Winning Supplier to Defense Supply Center Richmond (DSCR)

PKB is a regular recipient of the Gold Medal for excellent quality and on-time delivery for US Military Defense Programs. Pacamor Kubar Bearings (PKB), is honored to be named by the U.S. Defense Supply Center Richmond a Best Value Gold Medal recipient for demonstrating exceptional quality and delivery performance to the U.S. Government.

Michelle C. Skubic, Captain, SC, USN is Defense Supply Center Richmond’s Director of Aviation Supplier Operations for the Defense Supply Center Richmond Aviation Supply Chain.

Captain Skubic stated that the award is presented, “because of your company’s exceptional Automated Best Value System score” and congratulated PKB “for a job well done …efficiently supporting the warfighters.”

Pacamor Kubar Bearings (PKB)

145 Jordan Road, Troy, New York 12180

518-283-8002 – sales@pacamor.com

PKB is an American Owned & Operated Small Business, registered with the SAM.

PKB: Award Winning Supplier To Defense Supply Center Richmond (DSCR)

PKB is a regular recipient of the Gold Medal for excellent quality and on-time delivery for US Military Defense Programs. Pacamor Kubar Bearings (PKB), is honored to be named by the U.S. Defense Supply Center Richmond a Best Value Gold Medal recipient for demonstrating exceptional quality and delivery performance to the U.S. Government. Michelle C. Skubic, Captain, SC, USN is Defense Supply Center Richmond’s Director of Aviation Supplier Operations for the Defense Supply Center Richmond Aviation Supply Chain.Captain Skubic stated that the award is presented, “because of your company’s exceptional Automated Best Value System score” and congratulated PKB “for a job well done …efficiently supporting the warfighters.”

To more fully support the needs of our country’s defense programs, Pacamor Kubar Bearings has expanded its ball bearing factory capabilities, with four important new product lines. PKB is now producing Full-Complement Ball Bearings, Thin- Section Ball Bearings, Separable Angular Contact Ball Bearings, and Non-separable Angular Contact Bearings. PKB also offers legacy bearing products including Radial Ball Bearings, Cryogenic Ball Bearings, Metric Ball Bearings, Aircraft Bearings, and Specialty Ball Bearings. PKB ball bearings are manufactured at our ISO 9001:2015 and AS9100D certified factory in Troy, NY.

Ed Osta, President of Pacamor, stated, “Product quality from PKB is excellent. We’re a very customer focused business. Customers have made it known that these four products are desirable to them. Our customers are our greatest asset and our existence depends on responding to their ever changing needs. These four new products that we’re introducing today are a direct result of specific customer requests.”

Pacamor Kubar Bearings(PKB) continues to invest in its factory with the recent addition of a Cincom A32 lathe to its primary turn capabilities. This state of the art lathe expands machine capacity and production efficiencies within the Troy, NY ball bearing factory. The Cincom A32 is reputed to be the world’s fastest Swiss type CNC automatic Lathe. The new lathe enables PKB to shorten its uniquely compact factory lead time of 8-10 weeks for standard bearings and respond more quickly to new and unique ball bearing requests from the aerospace community. Enhanced products, as a result of this new lathe, will include shaft and bearing assemblies and expedited responses to time sensitive prototype requests.

518-283-8002

Customer Testimonial – PKB Bearings Outperform Competition In Flowmeter Application

Customer Testimonial – Ken Hoffer, CEO, Hoffer Flow Controls

Ken: “As you know for most of our meters we have used your bearings exclusively for a number of years, many are used on air calibrations for all sorts of gases and a large portion are used on liquid cryogenic such as LIN, LOX, LAR, LH2 etc.

“We used to advise after 3 months to a year that we recommend changing the bearings; several years ago we stopped changing the bearing. We have three people that calibrate and certify the cryogenic flowmeters all over the world, from China to South Africa, to Europe, Brazil as well as in the USA and Canada.

“We have not changed a bearing for years and have had no failures due to bearing wear, as a matter of fact we have found that when we do a repair for other reasons that a new set of bearing has a shift to the K factor, but when we go back to re-certify that the bearing has shifted back exactly to the original K factor which means that all the bearing are exactly the same which is amazing!!”

PKB: “Can you help us understand a little more about the “K factor”?

Ken: “The K factor is the number of pulses in a unit of measure I.E. gallons, liters etc. It is obtained by adding the individual K-factors for all the calibration points, typically 12 with the top and bottom points repeated, then divide the total by 12 and the resulting number will be the average K factor or number of pulses per unit. The meter will constantly reproduce this average K-factor for many years.

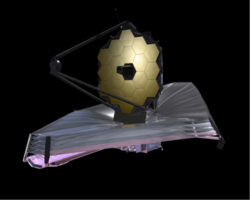

PKB Is Proud To Be Part Of The James Webb Space Telescope

The James Webb Space Telescope (sometimes called JWST) is a large, infrared-optimized space telescope. The project is working to a 2018 launch date. Webb will find the first galaxies that formed in the early Universe, connecting the Big Bang to our own Milky Way Galaxy. Webb will peer through dusty clouds to see stars forming planetary systems, connecting the Milky Way to our own Solar System. Webb’s instruments will be designed to work primarily in the infrared range of the electromagnetic spectrum, with some capability in the visible range.

The James Webb Space Telescope

Photo Courtesy of Northrop Grumman

Webb will have a large mirror, 6.5 meters (21.3 feet) in diameter and a sunshield the size of a tennis court. Both the mirror and sunshade won’t fit onto a rocket fully open, so both will fold up and open once Webb is in outer space. Webb will reside in an orbit about 1.5 million km (1 million miles) from the Earth.

The James Webb Space Telescope was named after the NASA Administrator who crafted the Apollo program, and who was a staunch supporter of space science. – http://www.jwst.nasa.gov/

Pacamor Kubar Bearings (PKB) extremely high precision specialty ball bearings are found in many challenging aerospace and defense applications. PKB’s specialty ball bearing designs are found in near-earth and cryogenic missions, life-sustaining survival suits for space exploration, public and private rocket launches and well known NASA space projects.

PKB manufactures a wide variety of specialty ball bearings for space vehicles, guidance systems, array mechanisms, flow meters and flow control units that are used in some pretty extreme environments like the James Webb Space Telescope or JWST.

Ball Bearing Steel: 440C Vs. 52100 In A Corrosive Environment

At Pacamor Kubar Bearings (PKB), we manufacture the vast majority of our miniature and instrument ball bearing rings from AISI 440C stainless steel, which is the standard material for most domestically manufactured miniature and instrument bearings for aerospace and medical applications. We also provide specially heat treated 440C for cryogenic applications or other extreme environments and occasionally manufacture ball bearings from other specialty steels.

There are some cases where customers ask for AISI 52100, a steel used in the bearing industry for many years but, in most cases has been replaced by 440C on newer drawing revisions and in new applications. The purpose of this blog is to offer some information about 440C as compared to 52100, particularly in corrosive environments.

According to “A Comparison of the Performance of AISI 52100 and AISI 440C Ball Bearings in a Corrosive Environment” Squires & Radcliffe, Central Energy Generating Board (CEGB-UK) Scientific Services & CEGB Berkeley Nuclear Laboratories, the results show that 440C stainless steel resists corrosion twice as well as conventional 52100 steel.

CEGB performed tests on 150 bearings made from En31 (AISI 52100) and AISI 440C materials and published their results in the Journal of Materials Science. “The clear conclusions were that the stainless steel bearings performed twice as well as the standard En31 bearings in terms of fatigue life, as well as being far superior both for corrosion resistance and for un-lubricated running.”

CEGB’s experiments compared the performance of AISI 52100 ball bearing steel and AISI 440C stainless steel. The bearings made from AISI 52100 had been suffering from corrosion damage in the application. The test atmosphere was moist carbon dioxide at a pressure of about 3 MPa, and bearings were deliberately contaminated with a representative amount of sodium chloride. The objective of the tests was to compare the rolling-contact fatigue performance of the materials and to look for other failure mechanisms in the ball bearings. Failure rates were found to be between 1 and 2 times more than would have been expected under ideal conditions. The failure mechanism was primarily identified as rolling contact fatigue. Results were analyzed statistically by assuming that failures fitted an exponential distribution, and it was shown that the stainless bearings performed more than twice as well as those made from conventional steels.

Some key points from the Journal of Materials Science article are provided here:

Lubricated Beaings – “During routine maintenance, superficial corrosion was discovered on certain ball bearings removed from components operating inside the pressure vessel of a CEGB nuclear power station. These bearings were grease lubricated, made from conventional En31 or AISI 52100 type steels, and compatible with their location in a relatively cool region of the reactor. It appeared likely that condensation of water on or near the bearings during moisture level executions had caused the corrosion, perhaps enhanced by the presence of chloride ions of uncertain origin. Although no operational problems had occurred, it was thought prudent to examine ways of preventing further corrosion.

One of the possible options was to replace the bearings with similar components manufactured from a corrosion-resistant steel such as AISI-440C. Whilst it was known that this would prevent the corrosion it was thought possible that the fatigue properties might be inferior. A search of the literature revealed no adequate comparative fatigue data even in air. In addition it was not clear whether, in the presence of chloride and of moisture, AISI 440C might be more susceptible to non-fatigue processes such a s stress corrosion cracking or hydrogen embrittlement.

Metallurgy – …A metallographic examination of unused bearings showed that the structures of the steels were fundamentally similar, being a matrix of tempered martensite containing chromium carbides.

Non-lubricated (Dry) Bearings – …As an additional check on the performance of bearings with no effective lubricant, un-lubricated bearings were run in two tests; the results were slightly unexpected in that the En31 bearings performed very badly, but stainless bearings performed quite well.

Failure Analysis – …About 150 rolling element bearings in conventional En31 and stainless AISI440C steels have been testing in a rolling-contact fatigue rig. The conditions simulated the temperature and gas pressure in a particular reactor, and the grease lubricant was artificially contaminated with sodium chloride. The dominant failure mode involved rolling-contact fatigue, and both materials had lives considerably below the classical expectations.

The reduction is thought to be an environmental effect related to the chloride and moisture levels, and more experimental work would be required to explain the various results. However the clear conclusions were that the stainless steel bearings performed twice as well as the standard En31 bearings in terms of fatigue life, as well as being far superior both for corrosion resistance and for un-lubricated running.”

Pacamor Kubar Bearings (PKB) – PKB AISI 440C ball bearings are found in dental and surgical handpieces, bone saws and drills, and fluid pumps for the medical industry. PKB produces 440C EMQ (electric motor quality) bearings for miniature motors, actuators, and electrical sub assemblies for robotic applications such as pick and place robots and packaging equipment. PKB 440C DFARS-approved instrument bearings are used in guidance and missile applications as well as specialty products produced for rocket booster components. PKB manufactures miniature and instrument ball bearings up to approximately 1.125″ Outside Diameter (28.57mm). Engineering assistance is available to help recommend or design a bearing for precision miniature applications. Please contact sales@pacamor.com