“Life” is the number of hours that a percentage of similar bearings have survived under an essentially identical set of operating conditions and loads. Life can be affected by a number of factors including loads, speed, lubrication, fit, maintenance, temperature, contamination, and others.

Bearing life is defined as the length of time (number of revolutions) until a specific failure occurs. Predicting the life of a ball bearing is a statistical calculation of the fatigue properties of the various bearing components. Fatigue Life (L10 or Rating Life) of bearings is the number of hours or revolutions reached by 90% of a group of bearings subjected to the same loads before the onset of fatigue. Conversely, 10% of the same group of bearings can be expected to show evidence of fatigue before the L10 Life is reached.

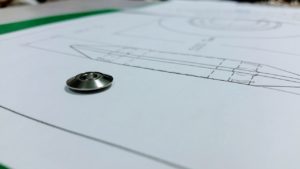

Many variables can impact bearing life. Various factors such as handling and contamination damage can dramatically reduce bearing life. Bearings should be properly stored, mounted, dismounted, and inspected. Optimized performance and life is also contingent on appropriate lubrication and sufficient protection from foreign matter. Bearings should be stored in a cool, clean, low humidity environment free of dust, shocks and vibrations. Proper fitting, using specialized tools and techniques, will also help maximize bearing life.

For further assistance with bearing selection and design, please feel free to contact our engineering team. Catalog bearings, of all sizes produced by PKB, can be configured as Angular Contact, Radial, or Full-Complement types. PKB also manufactures a wide range of Thin-Section and Metric bearings.

For further assistance with bearing selection and design, please feel free to contact our engineering team. Catalog bearings, of all sizes produced by PKB, can be configured as Angular Contact, Radial, or Full-Complement types. PKB also manufactures a wide range of Thin-Section and Metric bearings.

See our Bearing Installation Guide & Bearing Handling Practices pages for more information about proper installation of a PKB bearing into your device. Be sure to visit our Shaft and Housing Fits page for a detailed chart and more information about this topic.

For further assistance with bearing selection and design, please e-mail sales@pacamor.com