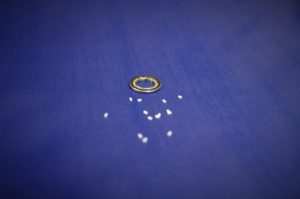

Ball Bearing Components

Retainers:

|

Steel Crown Offered in 410 stainless steel. This style cage “snaps in” over the balls. These perform well in low -torque, low-speed applications. |

Steel Two-Piece Ribbon Offered in 305 stainless steel. The two-halves are crimped together (rivet-style not available). These cages can can operate at low to moderately high speeds. |

Phenolic Linen-based material with ability to absorb lubricants. These cages withstand heavy inertial forces and operating temperatures up to 250°F (120 °C). Vacuum-impregnation also available. |

|

Meldin® Chemically resistant and compatible with all lubricants. Low thermal expansion, and stable at high temperatures. |

Aluminum-Bronze High strength, with operating temperatures of up to 500°F. Other useful properties include stiffness and ductility. |

Delrin® Features high strength and stiffness, with low moisture absorption. Good wear and abrasion resistant properties, and has a wide range of chemical resistance. |

|

Rulon High compressive strength, with low coefficient of friction. This material can be used in bearings and at temperatures from -400°F to 500°F. |

PGM Glass-fiber & Molybdenum Disulphide. It’s a self-lubricating composite which is used primarily within the space industry. Can be used up to 575°F. |

Peek Engineered thermoplastic. Performs well in high-speed or high temperature applications, and is a chemical resistant material. Great option for high-precision angular-contact ball bearings. |

|

Torlon Superior resistance to high temperatures. It is capable of performing under severe stress conditions at continuous temperatures up to 500°F (260°C). extremely low coefficient of linear thermal expansion. |

Slugs Teflon® PTFE bearing ball separators. Used in low torque and low speed applications. |

Toroids Teflon® PTFE. Used in low-torque and low-speed applications, and only available in Angular-Contact bearings. |

Closures:

|

Shields Offered in 300-series stainless steel, providing superior corrosion resistance. |

Double-Virgin Teflon® Seals Polytetrafluoroethylene (PTFE), AMS3652 non-critical grade. |

Double-Glass Reinforced Teflon® Seals Able to withstand aggressive environments. They have good wear resistance, low creep, and good compressive strength. Excellent chemical compatibility. AMS3666. |

|

Rubber Seals Buna-N rubber seals (acrylonitrile butadiene). These provide protection in contaminated environments. Max operating temperature is 240° F. (These are only available for certain PKB bearings; please inquire about options). |

Viton® Seals Synthetic rubber and fluoropolymer elastomer. Resistant to high temperatures, petroleum products, solvents, and a wide range of chemicals. |

|

Balls:

|

Steel 440c stainless steel balls are very strong, with fair corrosion resistance. They are resistant to water, petroleum products, organic materials, and steam. |

TiC Coating used in high-precision and instrument bearings. It has a strong resistance to lubricant breakdown. TiC coatings can also lower material transfer (microwelding), that causes metal-to-metal contact between the balls and raceways. |

Ceramic Silicon-Nitride (Si3N4) balls, for use in our Hybrid bearings(440c Stainless Steel rings). These balls are twice-as-hard as steel balls, having excellent fracture-toughness. They also have excellent corrosion resistance. |

Delrin® is a registered trademark of DuPont.

Meldin® is a registered trademark of Saint-Gobain Performance Plastics Corporation.

Teflon® is a registered trademark of DuPont.

Viton® is a registered trademark of The Chemours Company.

Please Note: Other machined retainer material available. Contact us with your specifications and/or requirements.