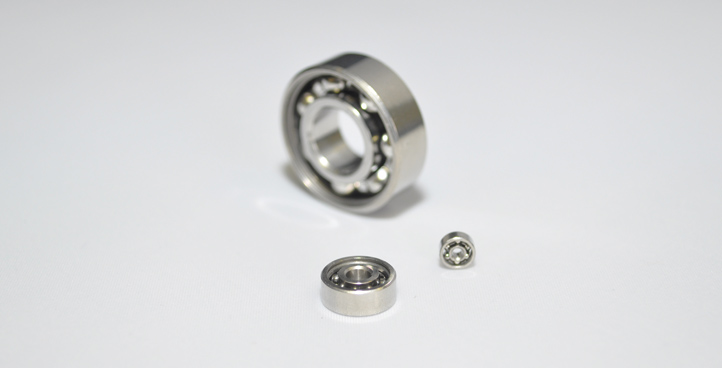

Ball Bearing Catalog

- Home

- Ball Bearing Catalog

Miniature-Inch Series

Miniature-Inch Series

Our selection of “Straight-Style” radial-inch bearings. All of the bearings we make are miniatures, but these feature a straight chassis, as opposed to a flanged, and/or extended inner option.

VIEW PRODUCTS

Full-Complement Bearings

Full-Complement Bearings

These utilize filling notches to maximize ball quantity, which eliminates the need for a retainer/cage. This design increases the radial load capacity.

VIEW PRODUCTS

Custom & Specialty

Custom & Specialty

These bearings could have “modified attributes”, including non-standard bores, outside diameters, widths, and internal geometry.

VIEW PRODUCTS

Miniature-Inch Flanged Series

Miniature-Inch Flanged Series

Our offerings with Outer Ring Flanges. The flange assists in positioning and mounting of the bearing.

VIEW PRODUCTS

Angular Contact Bearings

Angular Contact Bearings

These bearings can withstand high radial and axial loads, while reaching high RPM’s. Angular contact bearings are also highlighted in the use of Duplex-paired bearings (sets).

VIEW PRODUCTS

Ball Bearing Components

Ball Bearing Components

Our selection of Retainers/Cages, Closure-Types, and Ball Options.

VIEW PRODUCTS

Metric Ball Bearings

Metric Ball Bearings

Our bearing options, based on using the meter as a standard unit of measurement. The largest metric OD we can produce is 28.57mm.

VIEW PRODUCTS

Thin-Section Bearings

Thin-Section Bearings

Also known as “Thinex” bearings, Thin-Sections are designed for applications requiring low-friction and high accuracy, where mounting space is limited.

VIEW PRODUCTS